This article represents my own opinion and may contain affiliate links. Please read my disclosures for more information.

Kreg Mini Drilling Depth

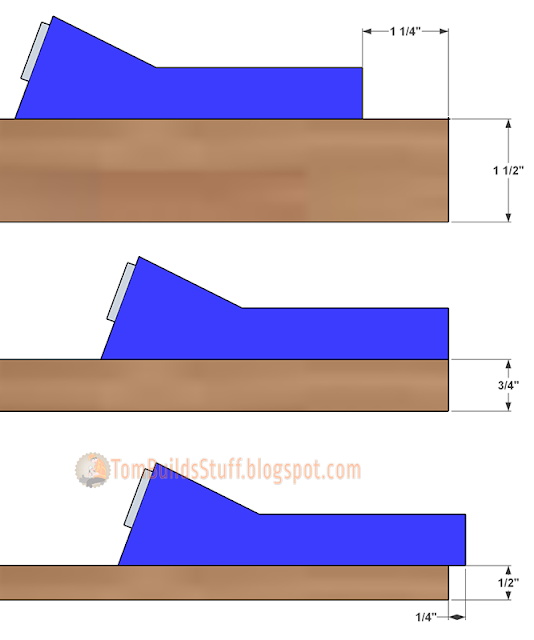

First you want to adjust the collar on the 2-set drill bit to control the depth of the pocket hole.

Kreg Mini Jig Position

Next you want to make sure you clamp down the Kreg-Mini the appropriate distance from the edge of the material based on the thickness of the wood you are joining.

Kreg Mini Setup

| Board Thickness | Depth Collar | Jig Distance From Edge | Screw Length |

|---|---|---|---|

| 1/2" | 3-5/16" | 1/4" Over | 1" |

| 3/4" | 3-1/2" | 0" | 1-1/4" |

| 1-1/2" | 4-1/4" | 1-1/4" Back | 2-1/2" |

The table above summarizes the Depth Collar Adjustment, Distance from Edge and Screw length for 1/2", 3/4" and 1-1/2" boards or plywood.

Great. Thanks for sharing. Very helpful.

ReplyDeletethis is really helpful but what about 2" wide material? what do i do?

ReplyDeleteLooks like they drop back 1/4" from what the depth is, so 1 3/4" back would be your setting

DeleteVery useful information. Thanks for sharing.

ReplyDeleteI am connecting two 1 1/2 in pieces with 2 1/2 in screws. I followed this direction using the jig 1 1/4 in from the edge. Once done, minimal pressure pulled the screws from the joint. What went wrong?

ReplyDeleteMichael,

DeleteHard to say. Can you link a picture with a 2-1/2" screw screwed in through one of the holes without the 2nd piece so I can see how much screw sticks out? Are you sure you measured the depth collar distance from the wide part of the step bit and not the tip of the bit? Did you make sure to drill all the way through until the depth collar stopped at the jig? What type of wood?

I'm no expert, but I gleaned info from other sites. One site says: Coarse-thread pocket screws hold best in softer woods, such as pine, cedar, and poplar, as well as plywood; use fine-thread screws for hardwoods. Choose the length based on the workpiece thickness.

DeleteMost pocket-hole screws come with an oversized washer head for increased contact with the pocket shoulder, but you can also get screws with a smaller pan head for use with shallow pockets where a washer head would protrude above the workpiece surface. For outdoor applications, choose stainless steel or coated screws. Never use drywall screws -- they break easily while driving, and their tapered ("bugle") heads can split the bottoms of the pocket shoulders.

Don't forget the glue. Screws alone make a plenty-strong pocket-hole joint, but adding glue helps prevent a joint from opening up due to seasonal shrinking and swelling.

How much do you off set it if you are using 1" thick material or 7/8" material?

ReplyDeleteMy wood is 5/8. Nobody talks about where to set the jig for 5/8.

Delete1/8th over

Deleteand what about the collar depth with 5/8 material

DeleteAlso what do you set the depth collar at for 1" material or 7/8" material?

ReplyDeleteGreat guide, found it when I Googled to find a guide when I was in the workshop

ReplyDeleteWhat is the bit depth for 5/8 material

ReplyDeleteWHERE WOULD I SET THE JIG FOR A 2" PIECE. IS IT POSSIBLE?

ReplyDeleteAwesome cheat sheet, thank you!

ReplyDeleteThat is absolutely fantastic. Thank you

ReplyDeleteHardly a cheat sheet, it's just a summerised version of what's in the manual.

ReplyDeleteThat's the definition of a cheat sheet...

DeleteThank you

ReplyDeleteWheres the mark to set for 1.1/2 on collar

ReplyDeleteThanks really help me

ReplyDeleteGreat help thanks.

ReplyDeleteThis is very helpful. Thanks. Seems Kreg don't provide much useful information on this little jig. Everything online is about the R3 on up.

ReplyDeleteSounds like we need the three equations - one for jig position from the edge, one for the position of the stop and one for the screw length. With that you could use the jig for any of the thicknesses above though I have my doubts if you can use it for 2" material. You might need to use the 1 1/2" setting and then put two or three more in the other face making sure they don't hit each other.

ReplyDeleteDo you have a fitting chart for using a Kreg Jig HD for thicker wood sizes? With an KJ-HD I want to join 2x8's but I cannot find anywhere collar depth and distance from edge settings! Please help!

ReplyDeleteA 2x8 is actually only 1-1/2” thick ssi use that from the table above.

Deleteand through all this you never answered what if the wood is a full 1" thick?

ReplyDelete