The idea of a wi-fi enabled thermostat that you can control remotely through your smart phone or computer is very appealing. Unfortunately most of the wi-fi thermostats I've run across have one major flaw. They require the use of an internet or cloud based system for remote monitoring capabilities which leads to a lot of problems and concerns. I've had my

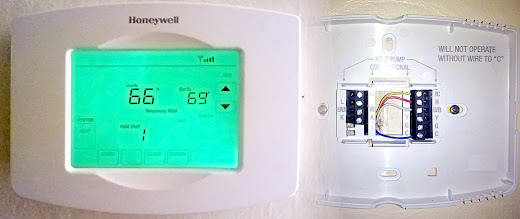

Honeywell Wi-Fi Programmable Touchscreen Thermostat RTH8580WF installed for over a month now and here are my issues with not only the Honeywell thermostat but other similar thermostats that can only be used with a 3rd party web service.

Continue Reading

How To Add C Wire To Thermostat

The thermostat I was replacing only controls my gas fired, hot water boiler which provides heat only. I didn't have to worry about cooling as my AC unit runs off a separate thermostat. There were three wires coming out of the wall where my old thermostat was mounted. My heating system only requires two wires, R and W, to operate. I thought I could use the third wire to power my thermostat and use that as the C wire. Unfortunately I ran into a couple of problems.

First, there wiring was very old and there appeared to be a break in that third wire. I couldn't get current to flow to it from the basement.

Second, and probably most importantly, I called the manufacturer of my boiler to double check that it would be okay to connect the thermostat to the C terminal on the 24 volt AC transformer in the boiler. These types of thermostats are called "power stealing" thermostats and the manufacturer (Weil McLain) does not recommend using a power stealing thermostat with my boiler. They were worried that the additional load from the thermostat may cause the transformer to prematurely burn out. They recommend using a separate 24 vac transformer to power the thermostat.

The instructions for the Honeywell Wi-Fi Programmable Touchscreen Thermostat (RTH8580WF1007/U)

Update: wi-fi on the thermostat sucks. You can only update the thermostat provided the thermostat can connect to the internet. Hurricane Sandy caused me to lose my home internet but I still had power and heat. When I went to bed the following night I was chilled do the bone having been outside most of the day dealing with the aftermath and i wanted to turn up the heat without getting out of bed but i couldn't because my internet was down. I could access all other wired and wireless devices on my network, just no internet access. There is no way to connect to the thermostat directly. It is all done through Honeywell's cloud service which it turns out collects my homes temperature readings and heating system information every 12 seconds. I don't like that and i don't like not being able to access the thermostat from home when my internet is down.

Change Your Thermostat Before It Gets Cold

With any project things can go wrong. You don't want to be in a position where it's the coldest part of winter and you're without heat for whatever reason!

Also check with your HVAC system manufacturer and thermostat manufacturer for specifics about your installation. Check with all applicable local building codes.

If snaking wire through walls and making electrical connections is not something you're comfortable with call an electrician.

What You'll Need

Materials

- New Thermostat (I used a Honeywell RTH8580WF)

- 24 Volt AC plug-in transformer (I used an MGT-2440

)

- 18 gauge thermostat wire. Number of conductors should be at least the amount of wires coming up from your HVAC system + 2 for the transformer. I needed a total of 4 conductors so I purchased the

Southwire 50 ft. 18/2-Gauge Thermostat Wire 64162179

. You may need more or less depending on how far you have to run the wire.

- 4 Wire nuts (one for each conductor you'll be using). Small ones, yellow or orange should do it.

- Fire Block Sealant

- Electrical tape.

Tools

- Needle nose pliers with wire cutter

- Wire stripper (if you're not comfortable stripping wire with a wire cutter)

- Philips head screwdriver

- Precision flat-head screwdriver (Like from the Stanley 66-039 6-Piece Jewelers Precision Screwdriver Set

)

- Fish Tape (I used Gardner Bender EFT-21PN 25-Foot Cable Snake Steel Fish Tape

)

- Caulking Gun

Step 1: Plan Your Wiring

I could have continued to use the 2 thermostat wires that were in my wall plus add 2 more wires that will run outside the wall to a nearby outlet where I would plug in the 24vac transformer. I didn't like this setup because I didn't want the wire to the transformer exposed where the thermostat was mounted. The installation would look much cleaner if all the wiring ran through the wall as it did previously.I needed 4 conductors. Two from the boiler and 2 from the 24vac transformer. The closest wire I could find was 5 conductor thermostat wire which is what I used. I was going to run the 5 conductor wire from my thermostat down to my basement and then I'd splice 2 more cables in the basement. One set of 2 conductors going to the boiler and two more going to the transformer which will be plugged into a wall. I used the same 5 conductor wire throughout (except for the connection between the boiler and new wire where I used the existing 3 conductor wire).

The 5 conductor wire will be snaked down the wall into my basement. From there I'll separate it into two runs. The Red and White will connect to an existing wire in my basement that goes into my boiler and connects to the R and W terminals on my boiler. The Yellow and Blue wires will run along another wire that goes to the plug-in 24vac transformer that will be plugged into a nearby outlet in the basement.

Step 2: Turn Off Your HVAC System

Before doing anything turn off the power to your HVAC system. This will vary by system but there should be some sort of switch near your system or there might be a breaker specifically labeled in your main circuit breaker panel.Step 3: Remove Old Thermostat

Your new thermostat will come with instructions and wire labels. Follow the instructions to label your existing wires with the stickers so you know which wire is which.

After you label your wires but before you completely disconnect them from the old thermostat, wrap a pencil around the existing wires and/or tape the wires to the wall the prevent them from slipping down into the hole.

If you need to drill holes for new wall anchors to screw in your new thermostat, do that now. Luckily I was replacing a different Honeywell Programmable thermostat that used the same hole spacing.

Step 4: Run New Thermostat Wire

This is the tricky part and how you run your wire is going to depend on how your existing wire is run. I was lucky and my thermostat had a straight run down the wall it was installed on down to my basement. By pulling on the wire from upstairs and down in the basement I was able to tell that the wire was not firmly stapled to the wall and I'd be able to pull it right out. The types of fasteners I saw used in the basement were fairly loose fitting. If that's not the case for you you might have a harder time snaking the new wire. You might have to make small holes in your walls here or there. Fishing wire can be tricky and you might want to hire an electrician to do this for you. Remember, it's best not to try and tackle this when it's very cold and you don't want to be without heat for a couple of days if something goes wrong.

Prepare Fish Tape

The first time I ever used the GB Fish Tape it was very difficult to get it out of the reel. You're supposed to pull the steel tape out by hand. It's coated in oil which makes it tricky. I took the tape outdoors, don't do this on carpet or the oil will stain it, and pulled out as much of the tape as I could by hand. Then I stepped on the end and pulled on the reel slowly working all the tape out. As my reach wasn't sufficient I walked down the tape to change where I was putting pressure. Be careful not to severely bend the steel tape when doing this. One I got all the tape out I reeled it in and repeated the processes. Now whenever I use the fish tape it comes out effortlessly.

Attach Wire to Fish Tape

From upstairs, where the old wire was coming out of the hole in the wall I attached the wire to the end of the fish tape. There's a small hole in the end that I passed the wires through and then used electrical tape to secure everything together. Make sure that the tape is put on neatly so that the point of connection isn't significantly thicker than the thickness of the wire. Tug on it a few times to make sure the wire isn't going to come off of the fish tape while you're pulling it through the wall.

Make sure you have enough fish tape unreeled to reach down to the other end of the opening.

Pull Wire Down

Next I went down to my basement where the old thermostat wire was coming out of the floor boards. I carefully pulled down on the old wire until the fish tape came down to a working level. I had to run up once to feed in the fish tape when it seemed to get a big snagged. This operation is easier if you have one person guiding the tape down from above and another pulling from below but is doable with one person.

Attach New Wire To Fish Tape

First I unspooled a sufficient length of wire and straightened it out a bit. I made sure to unspool enough wire that when I pulled the end upstairs the spool will still be on the ground so that the weight of the spool wouldn't pull the wire back down.

I stripped off about 1.5" of the brown outer wire wrap exposing the 5 individual colored wires. I passed those wires through the holes in the end of the fish tape. Then I took 3 of the individual strands one by one and wrapped them around the tip of the fish tape. Two in one direction and the other in the other direction. This will help secure the wires on the tape. Finally I securely wrapped the connection using electrical tape and tugged on it a few times to make sure it wouldn't come apart while pulling the wire through the wall.

I had taken a picture before I wrapped the connection with electrical tape to show you how I fastened the wire to the end of the tape. Unfortunately I didn't realize the photo didn't come out when I took it. The description above will hopefully be sufficient. Any way you attach it it's important that it provides some security and doesn't add much to the width.

Pull New Wire Up Through Wall

The first step is to start feeding the wire up from below until the connection between the fish tape and thermostat wire is past the hole. This is one of the points where the wire might snag. It's easier to do this with two people but I managed on my own.

Once the connection was through I double checked that the wire was straight and that there was enough unspooled.

Then I went upstairs and carefully pulled the fish tape up until the new wire came out of the hole in the wall.

I made sure I had enough wire to work with and I wrapped some tape around the new wire, while keeping the tape on the spool, to prevent the wire from slipping back down the hole. You could also wrap the wires around something like a pencil.

Step 5: Connect Wires to Thermostat Base Plate

With the new wire fished through the wall it was time to start wiring up the new thermostat. I trimmed the wire to an appropriate length so about 4 inches was sticking out of the wall. I'd deal with the mess of unwrapping the electrical tape off the end and fish tape later. I began by stripping a couple of inches of the brown outer wire sheath to expose the 5 individual color coded wires within. Then I wrapped the Green wire back against the main wire bundle since I wasn't going to be using it then I stripped about 3/8" off the end of the 4 remaining wires as shown.

Remove Jumper

The base plate of the thermostat comes with a metal jumper connected between Rc and R, it looks like a small staple. This jumper needs to be removed to be able to wire the thermostat to an independent power transformer. To remove it, use the small flat-headed precision screwdriver to loosen the two screws for Rc and R in the black terminal block. You don't need to unscrew them all the way, just until the tops of the screws are flush with the top of the black terminal block. Once both screws are loosened just pull the jumper out.

The Rc terminal is used for connecting the cooling relay. If your thermostat controls both your heating and cooling system I'm not sure how you'd go about wiring an external transformer. In that case you'd likely need to wire your thermostat's C wire directly to the transformer on your 24 volt HVAC system.

Attach Wires

One by one feed the end of each wire into it's appropriate terminal block and screw it down to hold it in place. The convention I'm using is:

- R - Red (to boiler)

- W - White (to boiler)

- Rc - Yellow (to transformer)

- C - Blue (to transformer)

Once the wires are attached you can secure the base plate to the wall. I used a small level on the side to make sure the base was mounted straight. (The top of the thermostat and base plate are curved.) The picture, didn't come out quite as straight :) but you can see how the 4 wires attach to the thermostat's base plate.

Depending on your HVAC system your wiring might be different.

Step 6: Connect Thermostat To Transformer

Back down in the basement and I ran the new wire to where the connection point to the wiring that goes to the furnace is. I think when they installed my new boiler they spliced in a new thermostat wire into the old one and the connection point is on a wall above the boiler. I ran the new wire to that point, gave my self a little extra to work with in case there where any mistakes and I cut the wire and stapled it securely to the wall.

Back down in the basement and I ran the new wire to where the connection point to the wiring that goes to the furnace is. I think when they installed my new boiler they spliced in a new thermostat wire into the old one and the connection point is on a wall above the boiler. I ran the new wire to that point, gave my self a little extra to work with in case there where any mistakes and I cut the wire and stapled it securely to the wall.

I then stripped off about 2" of the brown outer wire sheath. As before I wrapped the green wire back around the main wire since I wasn't going to be using it. Then I stripped off about 3/4" from the ends of the 4 remaining wires.

Next I determined where I was going to plug the 24 vac transformer in and measured out the appropriate length of wire from the spool. I knew I was going to have extra thermostat wire left over and I will be using that instead of getting a different 2 conductor wire since I won't need all 5 for this run.

After trimming the wire to length, I stripped off the ends of the wires and, wrapped the each around one of the 2 screw terminals on the transformer and tightened them down. The position of these two wires isn't important as this is an AC transformer. I picked this particular 24vac transformer (MGT2440) because it had the screw terminals.

Next I attached the yellow wire coming from the transformer to the yellow wire running down from the thermostat. I stripped the ends of both about 3/4", used pliers to wrap the wires around each other in a clockwise direction and secured them with an orange wire nut. I repeated the process for the blue wire from the transformer to the thermostat wire.

Before going any further I wanted to make sure the thermostat was getting power so I plugged the transformer in, ran upstairs, pushed the thermostat onto it's base and was happy to see the screen on :)

I had already configured to wireless settings when I was testing the 24vac transformer before I went through all this trouble.

Step 7: Connect Thermostat to Boiler

There was a 3 conductor wire running from the boiler to the old wiring for the thermostat. Luckily this new wiring was color coded so I knew which colors went to the R and W terminals on the boiler. One by one I attached the Red wire from the new wire that I ran from the thermostat to the basement by stripping off 3/4" off the new wire and wrapping it around the wire running to the thermostat R terminal in the boiler. The boiler wire was previously connected to the old wire and already stripped. I capped the connection with a wire nut and repeated the process for the White wire to the wire that runs to the W terminal on the boiler.

I flipped the switch to turn the power to the boiler back on and ran upstairs to make sure everything was working. I turned up the thermostat and checked to make sure the boiler fired up. While downstairs next to the boiler I used my phone to turn the thermostat down and within a few seconds the boiler turned off. :)

Step 8: Wrap Things Up

Now that I know everything is working correctly I wrapped electrical tape around the wire nuts to help keep them secure and I used the Fire Block Caulking in the opening from the basement up to the wall where the new thermostat wire runs. To be on the safe side I double checked that everything was working. Using the app on my phone I can adjust the thermostat from anywhere.

One of the nice things about having the thermostat plugged into the wall is that the light on the thermostat can always stay on and I don't have to worry about batteries draining. The thermostat is next to an opening I tend to bump into when I go down to grab a glass of water in the middle of the night. Hopefully no more stubbed toes and I never have to worry about replacing the batteries.

How To Cut Plywood With A Circular Saw

Since this circular saw cutting jig gets placed up against the cut line, it makes it much faster than other cutting guides that require you to offset the guide some distance from the line. The design also helps prevent splintering and tear out of the thin plywood veneer. Also see my new post for tips on cutting plywood square with a circular saw and my plywood cutting table plans that can be used with this plywood cutting jig.

Plywood Open Nightstand

Free woodworking plans to build simple nightstands out of plywood. Features a drawer and open shelving. You can build 2 nightstands out of 1 sheet of 4' x 8' plywood plus 3 quarter sheets for the drawer and back.

This is a relatively easy piece of bedroom furniture you can build with tools most DIY'ers have. Made from real plywood (since you choose your own wood) and not particle board like most furniture seems to be these days.

Dimensions

Dimensions: 22-1/2"W x 26"H x 19"

What You'll Need

Materials

The following material list will make 2 nightstands.

- (1) 3/4" 4' x 8' sheet of plywood or 4 2' x 8' quarter sheets

- (1) 1/2" 2' x 4' quarter sheet of plywood

- (2) 1/4" 2' x 4' sheets of plywood

- (86) 1-1/4" coarse thread Maxi-Loc pocket hole screws

- (6) 1-1/4" tapered head wood screws

- (4) 1" round head wood screws

- (2) pairs of drawer slides

- (28) feet of 3/4" veneer edgebanding

- Staples, brads or 3/4" wood screws to attach the back

- Wood glue

- Assorted sandpaper

- Stain/finish or primer paint

Tools

- Drill and assorted bits

- Circular saw with guide, track saw or table saw

- Kreg Jig

- Iron (for edgebanding)

- Measuring tape

- Pencil

- Screwdriver

- Utility knife

- Sanding block or finish sander

- Painting/staining supplies

Make sure you understand how to use all the tools properly and follow all safety precautions.

Cut List

- (4) 25-1/4" x 17-1/4" 3/4" Plywood Sides

- (2) 22-1/2" x 19" 3/4" Plywood Tops

- (2) 20" x 16-1/2" 3/4" Plywood Bottoms

- (2) 20" x 4-1/2" 3/4" Plywood Bases

- (2) 19-3/4" x 6" 3/4" Plywood Drawer Fronts

- (6) 20" x ~4" 3/4" Plywood Stretchers

- (4) 14-3/4" x 5" 1/2" Plywood Drawer Box Sides

- (4) 17-1/2" x 5" 1/2" Plywood Drawer Box Front/Backs

- (2) 25-1/4" x 21-1/2" 1/4" Plywood Backs

- (2) 18" x 14-1/4" 1/4" Plywood Drawer Bottoms

Cut Plan

3/4" Plywood

The main elements of the nightstand are made out of 3/4" plywood. You'll need 2 quarter sheets per nightstand or 1 full sheet to make two nightstands.

Note: Only one dimension given for stretchers. The length is the important measurement for the stretchers. You can make them any width that is easiest for you as long as they're at least 3" wide. Since I don't have a tablesaw to cut my plywood with, I usually cut the stretchers longer than necessary with my circular saw and guide and cut them to finished length with my miter saw once I'm ready to attach them after measuring the working cabinet.

Note: Only one dimension given for stretchers. The length is the important measurement for the stretchers. You can make them any width that is easiest for you as long as they're at least 3" wide. Since I don't have a tablesaw to cut my plywood with, I usually cut the stretchers longer than necessary with my circular saw and guide and cut them to finished length with my miter saw once I'm ready to attach them after measuring the working cabinet.

Full Sheet

Quarter Sheets

The cut plan below is for one nightstand. If you're making two you'll need to duplicate the cuts on the following 2 2' x 4' sheets for a total of 4 sheets. The formaldehyde freem

PureBond 3/4 in. x 2 ft. x 4 ft. Cherry Plywood 1703 from Home Depot is a good choice and they're currently eligible for free shipping.

from Home Depot is a good choice and they're currently eligible for free shipping.

1/2" Plywood

You'll need one sheet of 1/2" plywood to make the drawer boxes for both nightstands. A good choice for the drawer boxes is

PureBond 1/2 in. x 2 ft. x 4 ft. Maple Plywood.

1/4" Plywood

You'll need one quarter sheet of 1/4" plywood for the back and drawer bottom. Two if you're making two nightstands. Since part of the back will be seen through the open shelf it's important for the 1/4" plywood to match the species of the 3/4" plywood. You can use

PureBond 1/4 in. x 2 ft. x 4 ft. Cherry Plywood.

Step 1

Apply veneer edgebanding to the top of the Base and drill pocket holes as shown. Place the Bottom piece upside down on a flat work surface so you can attach the Base to it. Make sure the Base is also upside down so that the veneered edge is touching the work surface. Use wood glue and 1-1/4" coarse head screws to attach the Bottom to the Base through the pocket holes. Make sure the pieces line up and are square.

Step 2

Apply veneer edgebanding to the front edges of both Side pieces then attach one side at a time to the Base/Bottom piece from the previous step using 1-1/4" screws and glue. The bottom of the Side should be even with the bottom of the Base and the edge with the edgebanding should be on the same side as the base as well. Make sure everything goes together square.

Step 3

Make sure all three stretchers are the correct length to keep the nightstand square. Attach veneer edgebanding to one of the long edges of 2 of the stretchers. Drill 4 pocket holes in each stretcher.

Attach two of the three stretchers. One to the top front (with edgebanding out) and one on the back top (no edgebanding) as shown.

Step 4

Attach the 1/4" plywood Back to the back of the nightstand. You can use staples, 5/8" - 3/4" brads or 3/4" wood screws. If you screw the back on make sure to drill pilot holes and countersink holes first to avoid splitting the plywood sides.

Step 5

Cut the Drawer Front so that it fits in between the 2 Sides and the top Stretcher with about a 1/8" gap all around after applying veneer edgebanding along each edge of the Drawer Front. Measure the height of the Drawer Front and add 1/4" to it. That's the distance you need to screw the remaining Stretcher from the top/front Stretcher. Apply veneer edgebanding to the front of it and drill 4 pocket holes on the side facing the top stretcher.

Step 6

Build the Drawer Boxes. The measurements assume side mounted drawer slides that require a 1/2" space between the drawer box and side of the nightstand. You'll need to cut a 1/4" rabbet on the bottom of all the drawer side pieces to accept the drawer bottom. The easiest way to do this is if you have a router table. If you don't use can use a circular saw set at 1/4" depth.

When you're done with the drawer box, attach the drawer slides to the sides of the cabinet and the drawer box according to the specifications of the slide.

Step 7

Wrap all four edges of the top with veneer edgebanding. Drill pocket holes on the top of the Sides and the back Stretcher to attach the Top to the nightstand from underneath using 1-1/4" pocket screws. Use 1-1/4 wood screws countersunk into the front Stretcher. The back and the sides should have a 1/2" overhang. The front should over hang 1".

Step 8

Insert the drawer box into the drawer slides and place a strip of double sided tape on the front of the drawer box. Position the drawer front on the drawer box leaving an even gap all around. Press the Drawer Front into the tape to temporarily hold it in place. Carefully pull out the drawer by pulling on the drawer box from underneath and use 2 1" round head wood screws to attach the drawer box to the drawer front from inside the drawer box. Once secured drill the holes for your drawer pull and install.

Step 9

Prepare your nightstands for finishing by filling in any holes with wood filler, sanding and then removing all sanding dust. Prime and paint or stain and polyurethane how you'd like.

Computer Desk From 1 Sheet of Plywood

This attractive and functional computer desk is built using only one sheet of plywood and 14 cuts which makes it an easy and affordable desk that can be built with a few tools.

You can stain and finish it to reveal the the natural wood grain, paint it any color you'd like or mix painting and staining as in the black and maple desk example shown right.

The desk provides ample space for your computer and accessories as well as storage space for books, paper and other items you'll want to have handy while working on your computer. All this from just a single sheet of plywood!

Dimensions

48"W x 33 1/2"H x 23 15/16"D

What You'll Need

Materials

- (1) 4' x 8' Sheet of 3/4" Plywood (or 4 sheets of 2' x 4' 3/4" Plywood)

- (50') of Preglued Veneer Edgebanding

- (4) T-Nut Cabinet/Furniture Levelers

(optional but recommended)

- (61) Kreg SML-C125-100 1-1/4-Inch 8-Coarse Maxi-Loc Pocket Screws

- (3) 3/4" Corner Braces

- (6) 1/2" flat head wood screws

- (6) 1/4" Shelf Pins

- Wood Glue

- 220 and 120 grit sandpaper

- Painting and/or finishing supplies

Tools

- Kreg Pocket Hole Jig

- Drill

- Circular Saw with Guide, Track Saw or Table Saw for cutting plywood.

- Miter box or power miter saw

- Kreg KHC-90DCC 90-degree Corner Clamp

(highly recommended)

- Pegboard and 1/4" bit or Shelf Pin Drilling Jig

- Square

- Measuring Tape

- Pencil

- Sanding block

- Assorted painting and/or finishing tools

Make sure you understand how to use all the tools properly and follow all safety precautions.

Cut-List

Please note that if making the desk out of 4 sheets of 2' x 4' plywood that some of the dimensions will be slightly different. Quarter sheet dimensions are in parenthesis when they differ.

- (1) 48" x 23-15/16" Desk Top (48" x 24" one whole quarter sheet)

- (2) 26-1/8" x 23-15/16" Sides (24" x 26-1/4")

- (1) 46-1/2" x 12" Apron (46-1/2" x 12-1/4")

- (2) 46-1/2" x 1-11/16" Front (46-1/2" x 1-1/2")

- (1) 48" x 10" Shelf

- (1) 21-5/8" x 12" Storage Side

- (2) 21-5/8" x 11-7/8" Storage Bottom and Storage Shelf

- (2)10" x 5-7/8" Shelf Sides (10" x 5-15/16")

- (1) 10" x 11-7/8" Paper Tray (11.5" x 10")

- (4) 1-3/8" x 5-7/8" Paper Tray Supports (2 will be 7/8" x 5-7/8")

Cut Plan

For either full or quarter sheets the cut plans assume a maximum kerf (cut width) of 1/8" so it's important to use a thin kerf saw blade. The Freud Ultimate Plywood Saw Blade is a good choice for a thin kerf blade that will minimize tearout and splintering when cutting plywood.

Full Sheet

If using a full sheet of plywood, break down the sheet into three smaller sections by making the 2 cross cuts highlighted in red. First make the 48" cut, followed by the 26-1/8" cut. You can also break down the three sections further. The 48" and 26-1/8" section can be cut exactly in half (23-15/16 accounting for the 1/8" kerf) but the last section is not exactly in half (24")

Quarter Sheet

You save a little bit of money by buying one full sheet but it might be more convenient to purchase 4 quarter sheets instead. The smaller sheets are easier to transport and you can even have them delivered to you for free. If you're picking up the plywood you could have the store make some convenience cuts for you but the quality and accuracy of the cuts will depend greatly on the condition of the blade and how good the person operating the panel saw is at making accurate cuts. These convenience cuts are not guaranteed to be accurate.

General Instructions

It's important to know how to use all your tools and follow all the safety recommendations. This project consists of simple cuts but it's important to make sure to measure and cut each piece carefully. Square cuts in the plywood will make for a stronger desk. It's not necessary to glue the desk together as the pocket screws will provide sufficient strength and allow you to disassemble the desk at a later point if necessary. You will need to cut and assemble the desk first, then it is highly recommended to break it down again for finishing.

Step 1

Cut out the Desk Top, Sides, Storage Side, Storage Shelf, Storage Bottom, Apron and Front. Apply veneer edgebanding to all edges of the Desk Top, the 2 long edges of each Side and the front edges of the Storage Shelf, Bottom and Side.

Decide which side you'd like the storage to be on, the left or right, then choose that Side piece and the Storage side and drill a series of holes part way into the insides of the plywood for the shelf pins using either a piece of peg board or a shelf pin jig.

Step 2

Arrange the desk top and legs on the floor with the good faces facing out. Drill 5 pocket holes on the inside tops of each leg. The first hole towards the front should be about 1" in while the one towards the back should be about 1/2" in to accommodate the front strip and modesty panel (apron).

Align and secure each leg to the bottom of the desk top using 1-1/4" pocket hole screws. Make sure the sides are attached square to the top. Using the right angle clamp helps a lot.

Step 3

Attach the front strip flush to the front of the desk using 4 pocket holes with 1-1/4" screws on the back to attach to the sides and 3 3/4" corner braces with 1/2" flat head wood screws to attach to the top as shown below.

Step 4

Drill holes for pocket screws in the Storage Side and Apron (modesty panel) as shown. There is also a pocket hole going from the inside of the Storage Side into the Front which is not visible. First attach the Storage Side. Use the Storage Bottom as a guide to determine how far away it needs to be from the Side of the desk. Note that the Storage Side will butt up against the Front piece but will not extend all the way to the back of the desk.

Once you've attached the Storage Side, attach the Apron using pocket screws into the Sides and Top and from the Storage Side into the Apron. The Storage Bottom and Storage Side have the same depth, use the Storage Bottom as a guide on the opposite side of the Storage Side to press the Apron against so you screw it in straight.

Remember, the Apron will not sit flush with the back of the desk. Here's a rear view.

Step 5

Attach the Storage Bottom using 1-1/4" pocket holes as shown. If you're installing the optional leveler feet do so now.

The main part of the desk is now complete.

Step 6

Cut out the components for the Shelf. These include the Shelf, 2 Shelf Sides, Paper Tray and Tray Supports. Apply veneer edging all the way around the Shelf, on 3 edges of the Papery Try (not the edge touching the side), on the 2 short edges of each Side and on the 2 long edges of each of the Tray Supports.

Begin shelf assembly by attaching the two Shelf Sides to the Shelf Top using 1-1/4" pocket hole screws as shown.

Step 7

Drill 1 pocket hole in each of the tray supports to attach it to the top. The pocket holes should be on the inside of the support. Use the Paper Tray butted up against the side where you'd like to install as a guide to determine how far away the Supports should be. The tray supports should be evenly spaced 1.5" apart with the two end pieces flush with the edges of the Shelf Top.

Step 8

Now attach the paper tray at the midpoint of the sides and supports to split the space evenly using 1-1/4" pocket hole screws as shown. 3 into the Shelf Side and 1 into each Tray Support.

Step 9

To prevent the shelf from sliding around on the desk but still be able to easily remove the shelf at a later point if desired we'll be using 2 shelf pins to anchor the shelf to the desk.

Begin by placing the shelf on top of the desk and aligning it flush with the sides and the back of the desk top. Using a pencil, mark a vertical like halfway into the shelf side extending down into the side of the desk top as shown.

Use a square to transfer the marking onto the desk top as well as the bottom of the shelf side. Measure in 3/8" on that line and mark it. Using the shelf pin drill bit drill a hole into the top of the desk as well as the bottom of the shelf side. Do this on both ends for a total of 4 holes, 1 in each shelf side bottom, and two on the desk top.

Take your time and be very careful with these measurements so they line up properly. Once you have all 4 holes drilled, fine tune them by slightly deepening or widening the holes in the Shelf Sides. Finally insert a shelf pin in each hole on the Desk Top and slide the Shelf onto them.

Step 10

Your desk is now complete and is ready to be finished with either primer/paint or stain/polyurethane or a combination of the two. It will be easier to finish some sections if you take the desk apart first. Just follow these directions backwards to take everything apart. Then follow the directions on how to put all the pieces together again.