Free woodworking plans to build a wall-mounted can organizer for storing, rotating and organizing canned food. Simple and doesn't require a lot of tools.

About the TBS Can Rotator

We're going through some difficult times in the NYC area with the coronavirus pandemic and I want to make sure I have enough food in case the lockdowns get tighter. I've been trying to keep a weeks worth of fresh food, another week's worth of frozen food and then some canned food and dry food to get through a week. My canned food game was pretty weak so I wanted to come up with a new system to be better prepared for emergencies.

I wanted to create a canned food organizer that:

- Had a FIFO (first in first out) design so that older cans get used first

- Didn't take up a lot of space and could be hung on a wall if you don't have a pantry

- Was easy to build without a lot of tools or experience

- Didn't cost a lot to make

- Could provide at least one well-balanced meal a day for 1 week for one person

This is what I came up with

It's a 2'x2' wall mounted

can dispenser that has 5 compartments, 4 for standard 15oz cans and 1 for 5oz tuna fish sized cans. Each of the 15oz columns can hold 8 cans while the tuna column can hold 7 cans of tuna for a total of 39 cans. When I'd like to use a can I pull it out from the bottom. When I add new cans they go in at the top so I'm rotating the stock.

With some other pantry items like rice, oatmeal, peanut butter, jelly, whole grain crackers, each TBS 2x2 Can Rotator can help provide 3 meals for 16 days to one person, or 8 days to two people. I can achieve over 2,000 calories a day with the following meals.

Breakfast: 1 cup dry oatmeal cooked in water with 2 tablespoons of peanut butter.

Lunch: 1 cup instant brown rice with 1/2 can of tuna fish, hopefully lettuce from garden.

Snacks: 2 whole wheat crackers with peanut butter and jelly, trail mix and canned fruit.

Dinner: 1/2 a can of non-starchy vegetables (green beans/mixed veggies), 1/2 a can of beans (garbanzo beans), 1/2 can of no-bean chili,

You may want to stock your Can Rotator with other items but this is what works for me and the type of canned items I can work into my regular menus so that I'm keeping the cans fresh.

It can be built without any power saws. Some pieces will need to be cut but they can be cut with a hand saw or have them cut at the store. The only tool power tool necessary is a drill which a lot of people have and if you don't have one I'm sure you can find a friend to borrow one from.

What You'll Need

I chose items that are currently in stock at my local Home Depot.

Materials

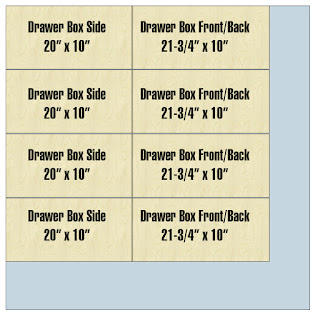

- (1) 1/2" 2'x2' Plywood (back)

- (2) 1/2x4 4' poplar board cut in half to roughly 24" each (center dividers)

- (2) 1x4 2' long poplar boards (sides)

- (2) 1/4x3 4' poplar board cut into 4 19" lengths, 1 10" and 1 9" piece (fronts)

- (1) 1x6 2' poplar board (bottom)

- (1) 1x2 2' poplar board (front lip)

- Kreg 1" screws

- Kreg 1-1/4" screws

- 1-1/2" Common nails

- Wood Glue

Tools

- Drill

- Kreg pocket hole jig, the mini will work and currently costs only $14 but see my post to decide which Kreg Jig to buy for other options

- Clamp

- Tape measure

- Straight Edge

- Pencil

- Hand saw with miter box

- Hammer

Step 1: Attach Lip to Bottom

Drill the holes for the pocket screws on the 1-1/2" side of of the 1x2 board. It's a little tricky to get it since it's a short board but it works.

If you're using the Kreg Mini, the base of the mini will go flush up against the end of the board. See my

Kreg-Mini Cheat Sheet for more info on using the Kreg Mini.

Apply a thin layer of glue on the side of the 1x2 that will press up against the bottom 1x6 board then position the lip on the bottom so it's flush with the front as shown in the picture. Use 1-1/4" Kreg pocket screws to join the pieces.

Step 2: Attach Back to Bottom

Now drill 5 or 6 evenly spaced pocket holes along the bottom, back edge of the 2'x2' plywood as shown. Use glue along the edge of the plywood and secure it to the bottom board using 1-1/4" screws.

Step 3: Attach Sides

Drill 2 pocket holes on the bottom of each side and 5-6 along the long back edge as shown. Apply wood glue to the back and bottom edges of the plywood and attach each side flush to the back and bottom using 1-1/4" Kreg screws.

Step 4: Attach Center Dividers

The center dividers are 1/2" thick so we'll be using 1" Kreg Screws and using the Kreg Mini Jig it won't be flush with the wood but will stick out 1/4" out from it. (See my post on

using a Kreg Mini). You can use a 1/4" spacer if you have one. If you don't have an easy way to set the Kreg Mini to 1/4" overhang you can stack 4 pennies together to use as a spacer which will get you close enough or use one of the 1/4" front boards. Place the holes in a similar fashion to the sides, 2 on the bottom, 5 or 6 on the back.

Space out the dividers to create the columns as shown. The thin column for the 5oz tuna cans will need to have 1-5/8" of space. The other will all be 4-3/4" except for the one next to the thin column since we stole 1-1/8" from there to have a little more room.

Apply a thin layer of wood glue to the back and bottom edges of the 1/2" dividers and screw them into place with the 1" screws.

Step 5: Attach Front Slats

At first I was going to use a clear sheet of 18"x24" acrylic for the front to hold the cans in place which I thought would look nice and allow a full view of the cans but then I realized it wasn't ideal. When a column is empty and you're adding cans, the can is going to have a long way to drop which could damage the can organizer over time or even damage the can. By putting slats int the front the way I did it holds the cans in place, allows you to see the cans and you can also gently guide the can down when filling it up. It also wound up being cheaper.

The 1/4" thick boards are 19" long, except for the last one which is 2 10" left over pieces from cutting the other pieces.

They'are attached to the sides or dividers using wood glue and 1-1/4" nails. Drill pilot holes before hammering in the nails to prevent splitting the wood.

My Pantry Can Organizer

The above plans are for a self-contained, FIFO, canned food storage system. I couldn't actually fit that easily into my own pantry but I used the basic components and layouts to come up with something that fit my space better. Well almost the same components. I made a mistake ordering the 1/4" boards and got 1/4 x 4 boards instead of 1/4 by 3 :(

It's also a little deeper since I used existing shelf slats to screw the dividers into. It still works as intended but the cans don't stack as neatly inside. On the plus side I was able to fit in an extra can.

It still needs some cleaning up, sanding, hole filling and painting but for now it's serving it's purpose. At least once a month I will pull one can from the bottom and use it in a recipe and replace it with a new can in the top. This way my can's are never more than 9 months old.